Following a competitive bid process led by Protean Electric, a global leader in automotive technology and in-wheel motor solutions, we will be collaborating with Protean and its other partners – Unipart, Viritech, and Hypromag to deliver the Power-electronics Upscale for Localisation and Sustainable Electrification (“PULSE”) programme. The PULSE programme aims to bring cutting-edge UK-developed power-electronics products and manufacturing capabilities to the EV market.

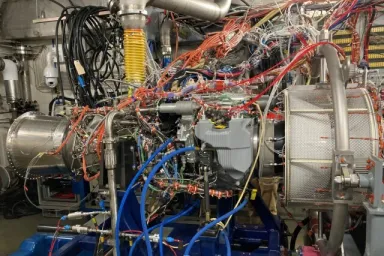

We are contributing our SAWsense technology to enhance Protean’s in-wheel motor assemblies, improving control and performance. This involves integrating SAWsense sensing elements within the motor system, along with electronics and control software, as part of Protean’s new 800V Twinverter system.

The 30-month PULSE project will build on Protean’s Gen5 in-wheel motor technology by developing an advanced 800V Silicon Carbide (SiC) Twinverter and in-wheel motor for use in both lightweight and heavy-duty EVs. This project will also focus on creating an integrated drive unit to meet growing demand in the EV market.

As part of the project, we will also be investing in developing our supply chain and manufacturing capabilities, ensuring readiness to meet automotive market production and quality requirements to support Protean’s market launch.

Ryan Maughan, Managing Director of Transense Technologies plc, commented:

“We are thrilled to be a part of this groundbreaking EV drive system project, propelling the UK’s automotive industry toward sustainable electrification. Winning such a competitive bid is a testament to the confidence in our SAWsense technology and our team’s expertise. This project underpins our near-term revenue forecasts and presents long-term opportunities for production revenue.”

Stephen Lambert, CTO of Protean Electric, added:

“Project PULSE brings together a world-class consortium to develop in-wheel motor power electronics and the manufacturing solutions needed to manufacture in volume. We are delighted to be working with Transense to deliver motor-integrated torque sensing technology, having seen the potential in initial feasibility and technical studies that have already been completed.”