Electric Motors and Drives (EMD)

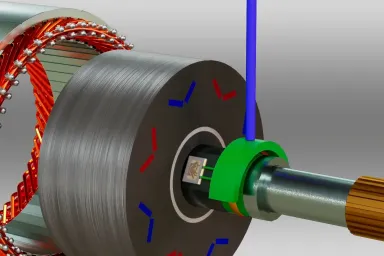

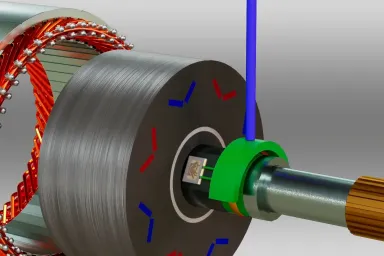

As the market for electrified vehicle powertrains develops rapidly, the quest to deliver improved efficiency and performance in electric drive…

Applications

Off-highway machinery and Industrial Robotics provides the backbone of many sectors, from mining and construction to agriculture, materials handling, manufacturing and logistics where Transense SAW sensors can be used.

SAW sensor technology can provide an improved way to measure torque, rotation, and temperature in robotic systems. Measuring torque and forces without reducing the mechanical integrity of the part, and virtually eliminating flex, creating high-performing and more repeatable robots with more compact joints than has previously been possible. SAW technology is robust and reliable, offering a highly accurate and high-speed measurement of torque, force and temperature, creating new possibilities in robotic system design and control.

Integrating torque measurement and control into the motor control of the robot can help to deliver faster and more stable operation of the robot, significantly reducing torque ripple and dynamic overshoot problems. SAW technology can be applied to a joint sensor, but it is also possible to deeply integrate it into the gearbox or drive motor, making more compact joint designs a possibility.

SAW sensors can also enable measurement over a joint with a full rotation of >360°, such as in the robotic wrist joint. With force/torque sensors now becoming an essential part of cobot motion system, SAW technology provides a greatly improved sensing solution compared to conventional sensing technologies.

Surface acoustic wave technology can also provide solutions for off-highway manufacturers to measure torque and/or temperature, wirelessly, in real-time. This capability allows torque measurements to be used in the machine's control system to improve accuracy, efficiency, and power distribution. This can also contribute to the ability to operate such machines remotely or on a fully autonomous basis and reduce unnecessary breakdowns and costly downtime.

Transense SAW sensor technology measures torque without requiring shaft torsion/flex, meaning the mechanical integrity of the component being measured can be maintained, creating new possibilities for improved machine control. It can be directly embedded into machine axles, driveline and accessory drive systems to accurately measure the torque being transmitted. Helping to control traction and power distribution in these critical machines.

SAW sensor technology can be applied to industrial engines to improve efficiency, performance and reliability. Embedding SAW technology into the output shaft of the engine, provides a high speed and accurate verification of the engines performance and output, which is fast enough to be used to detect issues such as a problem with a particular cylinders firing in many applications. This provides the ability to diagnose and manage combustion system faults and prevent potentially dangerous failure modes such as fuel dump into the exhaust system.

In addition to torque measurement, there is often a need to measure temperatures in moving parts and systems on industrial machines and engines to protect the machine and manage its performance. SAW technology enables the accurate measurement of temperature on moving components with a reliable, non-contact and passive sensing system. Applications range from measuring the temperature of conductors in high-voltage/current electrical equipment to the temperature of components inside industrial engines. SAW technology provides a reliable temperature measurement solution.

As the market for electrified vehicle powertrains develops rapidly, the quest to deliver improved efficiency and performance in electric drive…

The measurement of torque is common practice in all types of aerospace engines and is used to improve safety, pilot control, and engine reliability.…

Transense has partnered with McLaren Applied for Motorsport torque-sensing systems.