who will mandate the part across all entrants. This next-generation product is designed specifically for the series’ new hybrid era, which will debut in 2024.

The new torque sensor is a non-contact measurement device based on Transense's SAW technology which uses small sensors, is lightweight, robust, and provides accurate wireless measurement. Each shaft is supplied with a calibration file and is actively thermally compensated over its operating temperature range, further improving precision.

SAW sensors measure torque by using electricity to generate RF (radio frequency) waves. These acoustic waves are reflected off a piezoelectric surface, which deforms in line with the amount of torque the shaft to which it is applied is being subjected to.

By detecting and interpreting the change in the frequency caused by this deformation, a SAW sensor can accurately and reliably communicate a torque measurement for any rotating component, such as the gearbox input shaft or driveshaft. This data can then be used either by teams themselves to measure and control vehicle performance, or by governing bodies to enforce regulations and ensure a level playing field.

The new generation SAW sensor makes use of an AQP (All Quartz Package) that greatly aids the simplification of the shaft machining, reduces weight, and provides greater resistance to ingress of moisture and contamination, delivering even greater value to all teams on the grid. This also results in a more sustainable product as it does not require the yearly recalibration of previous magnetostriction-based sensors.

Transense COO, Nick Hopkins, said of the project:

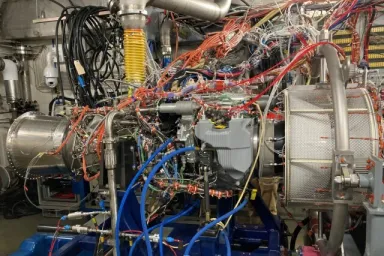

Transense is particularly pleased to be collaborating with McLaren Applied for these applications, which offer real benefits to the users while showcasing the technology in a demanding and challenging environment.

Read about McLaren Applied's SAW Sensor - Torque Measurement System

Learn more about SAW technology by following Transense on YouTube and LinkedIn